Johan Seljeson, site manager for Skandinaviska Byggelement has a good reason to be smiling these days. Since 2017, the plant’s production has been growing steadily – from 90,000m2 to 130,000m2 in 2018 – that they have set a goal of producing 180,000m2 of hollow-core slabs by the end of 2019. One of the reasons he thinks they are able to do it is because of the increased efficiency offered by FloorMES.

“We have good people on staff that know what they’re doing plus the Elematic machines are reliable on the production floor. We have also benefitted from the data that we get from it; the overall view that it gives on production has been invaluable.” Skandinaviska was literally one of the early adopters of the FloorMES. “The FloorMES software was still in development when we bought it. With our input, Elematic has changed a lot of things, improving it every time. And because we use the system daily, we sometimes notice things that we missed or features that we want. Elematic has always been quick to implement those,” Seljeson says.

Finetuning efficiency

Skandinaviska is a relatively young company, and the hollow- core factory an even younger one, a fact that Seljeson sees as an advantage. “Because we’re all relatively new to this, we approach things with openness. We don’t have the mindset that ‘this is how it’s always been done.’ If we get an idea, we try it.

If it doesn’t work, at least we tried. I think this is one of our biggest strengths. We’re a young factory; we’re hungry; we always want to do things better.”

Aiming to do things better is one of the reasons why Skandinaviska chose the FloorMES. “We knew we needed to go more digital in production if we were to increase our production volume. We needed a way to get an overall look at what was happening at any stage of production, so we can identify the bottlenecks and solve them.”

According to Seljeson, an overall view is exactly what the FloorMES gives them. “We know what the day or the week is going to look like. We can tell when we need to get more people in the process, where we need to put in more effort. It really contributes to a smoother production process, making it more efficient.”

The data they gather have helped Seljeson and his colleagues make decisions based on facts, not guesses. “At any moment, we can check how long a process in the production chain takes. If a process takes longer than usual to complete, we know where we need to focus our attention on. We don’t have to spend days in meetings trying to figure out where the process went wrong because we can just look at the data.”

“We adopted the FloorMES just a year and a half ago and we haven’t even scratched the surface of what the software is capable of. For now, being able to visualise bottlenecks so we are able to resolve them faster is the biggest thing we use it for, but we still have a lot of things to learn about what the program is capable of delivering,” Seljeson explains.

Helping build a new Gothenburg

Finding a way to raise efficiency on the factory floor is certainly going to come in handy. Skandinaviska has been chosen to deliver the slabs for Platinan, a mixed-use construction in the heart of Gothenburg. The 18-story building will include a hotel, offices, event venues and restaurants.

Platinan is more than just a construction project. Commissioned by Vasakronan, the office block is part of the development plan for the city, called Vision Älvstaden (or RiverCity). This is the first project in the big development package for Skandinaviska and its parent company Peab. Platinan’s architecture is unique, with large glass façades and permeated by sustainability. The building is being constructed according to LEED certification and aims to achieve the highest level – Platinum.

“The project is 60 000m2, roughly a third of our projected production this year. This is the biggest job we’ve had. It feels really good to get that vote of trust from the buyer.

The quality of the slabs we make in the factory has been up and rising. And it feels like a validation to get these big jobs,” Seljeson affirms. Platinan will be flanked by the new Hising Bridge, offering renters a view of the river. Construction has already started and the project is expected to be completed between the end of 2021 and early 2022.

On the frontline with Elematic

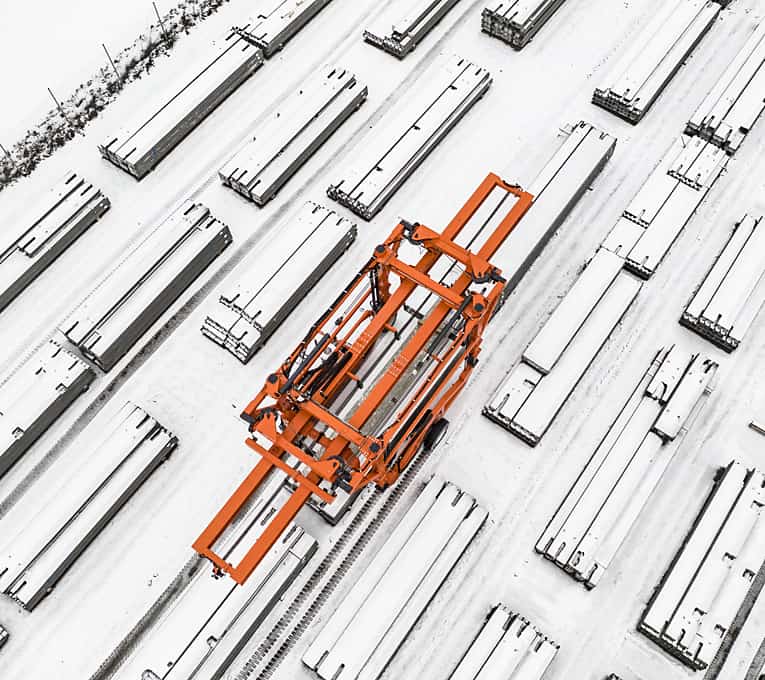

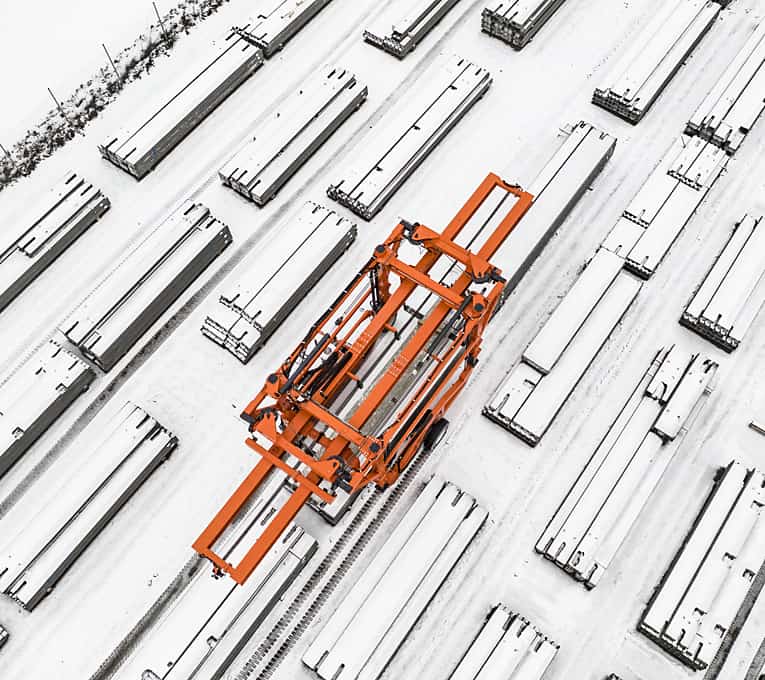

Skandinaviska’s hollow-core factory in Hallstahammar was delivered by Elematic five years ago. They now have six products: 200Heavy, 200, 265, 320, 380 and 400mm. They’ve been so impressed with the factory’s performance that they’ve ordered two of each – power units, saws, preparers – so production doesn’t have to stop for maintenance work.

Seljeson believes that the partnership will go on long into the future, especially in digitalisation. He definitely has plans to digitise more processes in the office and in production to improve efficiency even more. “We want to have a barcode system that will allow us to get all information and follow any slab we manufacture at all stages of production and beyond. We’d like to move away from paper blueprints and use tablets instead. We’re looking forward to so many things happening in the future and I believe we will be in the frontline of digitalisation together with Elematic.”